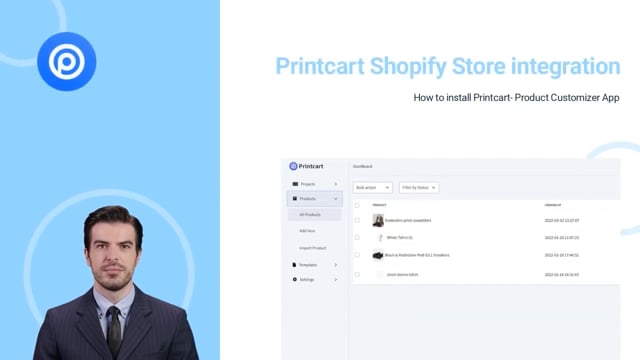

ENTERPRISE ECOMMERCE DEVELOPMENT

At Printcart, we power your printing business with full eCommerce solution to manage business process on Clients

ENTERPRISE DEVELOPMENT

At Printcart, we power our partner with full eCommerce services

StartUp Project

Printcart helps Tech Startup to launch eCommerce websites that showcase MVP products or SaaS services with recurring subscription payment

Digital Tranformation

Printcart works closely with printing businesses to provide the consultancy and digital workflow during their moving toward eCommerce technology

SME Business

Printcart provides the best website themes and extension development services for SMEs based on eCommerce platforms

Enterprise Corporation

Printcart is being an eCommerce partner and tech developer for many corporations in the EU, the US, and Asia with high volumes of works and transaction

ENTERPRISE OPTIMIZATION

At Printcart, we power your Printing Business with custom projects to optimize the business process

ON DEMAND DEVELOPMENT

We have done over 10k ecommerce project

Read over 1000+ testimonials

A robust congratulations to the team at Printcart for a job well done.

We've been trying to put together a functional website since I began my practice in April of 2015. I am happy to say we finally hired the Printcart team and they've worked closely with us throughout the process, staying on task, on target, and on budget.

I also appreciate their quick and courteous responses. I highly recommend their service!

Innovative

Techology

for enteprise ecommerce

Recently, we discovered how client loving working with us by their 5 star recommedation

Top